Brand: Houming

Species: Oriented Silicon Steel

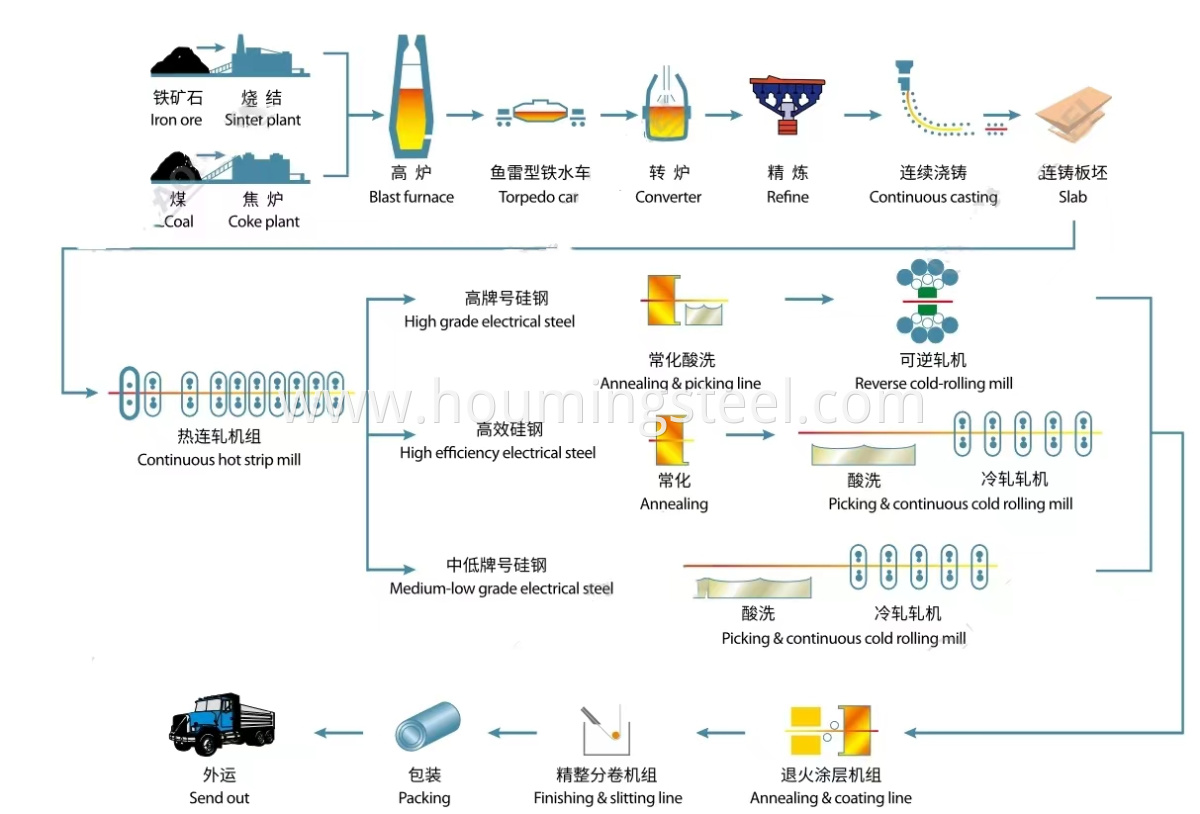

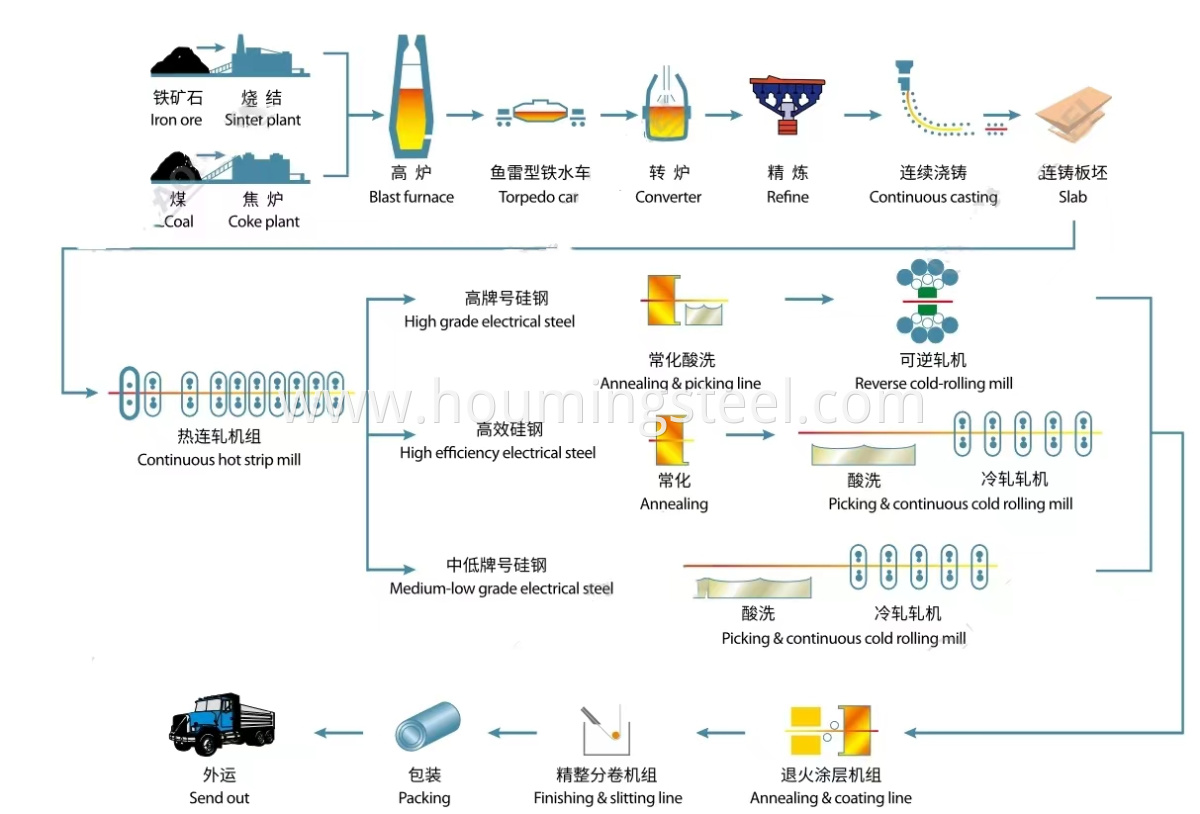

Production Process: Cold Rolled

Surface Treatment: Coated

Shape: Steel Coil

Standard: Gb, Astm, Aisi, Din, Bs, Jis

Place Of Origin: China

Tolerance: ±3%

Processing Service: Decoiling, Welding, Cutting

Packaging: Standard Seaworth Packing

Productivity: 5000 ton per month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 8000 ton per month

Port: Qingdao,Tianjing,Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

Cold rolled garin-oriented silicon steel

Cold rolled grain-oriented silicon steel, also called CRGO silicon

Steel Coil or CRGO electrical steel. It is one kind of

Cold Rolled Steel Coil. It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N)

CRGO advantage: 1. CRGO has strong magnetic directionality;

2. Resists internal oxidation during stress relief annealing;

3. Enhances lacing of transformer cores into windings due to reduced surface friction;

4. Reduces interlamination eddy current losses due to the insulating quality of the coating;

5. High stacking or laminating factor allows compact core designs.

Product application: Grain-oriented silicon steel's orientation improves the magnetic properties of silicon steel, giving it better performance in electromagnetic devices such as:

1. Motors

The non-grain oriented electrical steels are good choose for compressors and air conditioner motors as its high mechanical resistance, high magnetic induction, and low magnetic loss at high frequencies. The non- grain oriented electrical steel can keep equipment operate long time.

2. Transformers.

The non-grain oriented electrical steel can be used in large induction motors due to their energy efficiency, maximum durability, robustness, and resistance.

3. Generators

Power generators and hydro generators needs ultra-low magnetic losses to add their energy output and performance. As the non-grain oriented electrical steels are perfect for generators.

Except above, electric vehicle motors, large DC, motors, high-frequency motors, medium frequency motors, aviation, transformers etc.

Processing flow:  Product details:

Product details:

| Thickness: | 0.23-0.30mm |

| Width: | 850-1200mm |

| Length: | Customised as customer's requst |

| Inside diameter: | 508+/-10mm |

| Coating | C-0, C-3, C-4, C5, C-6 we can customised as your requst |

Cooperative partner:

How to choose suitable CRGO steel coils for you?

1. Understand own inquiry

Different applications need different properties. For example, transformers need oriented silicon steel, while rotating machinery might benefit more from non-oriented silicon Steel Plate.

2. Cost

Oriented silicon steel tends to be more expensive than its non-oriented counterpart due to the additional processing steps, so you can choose as your budget.

3. Size

Large components might be better suited to non-oriented silicon steel, which is less sensitive to mechanical strain, so you need take the application size into consideration.

4. Environment

The operating environment factor could influence your choice. For instance, silicon steel with higher curie temperatures may perform better in high-temperature applications.